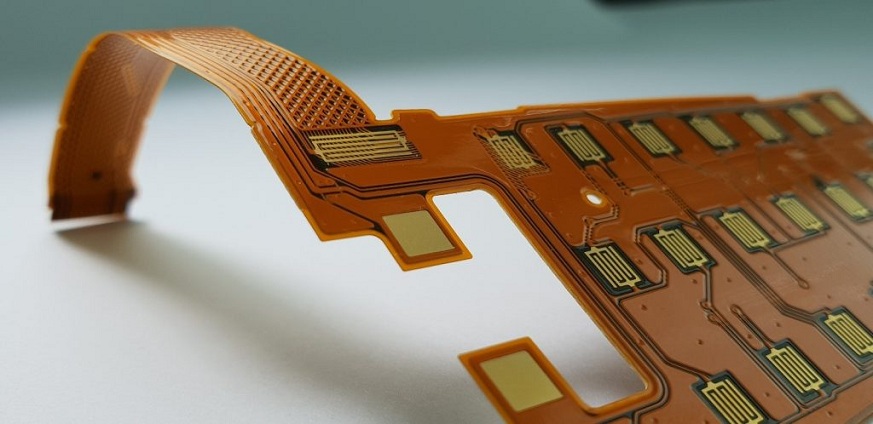

For many years, traditional rigid printed circuit boards ruled the untold world of electronics, always remaining the safe bet standard for pcb design engineer. However, as the technology progressed and developed in unexpected directions, the demand for more versatile and compact solutions opened up the scene for flexible PCBs. Introducing a blend of flexibility and durability, flexible circuit boards broke through to find applications in virtually every industry. Consequently, they empowered designers to put innovative ideas to material form thanks to the opportunity of seamlessly integrating the circuit into a curved or irregular-shaped end device. While they withstood extensive bending and twisting, they quickly became an excellent choice for applications such as LED lighting and consumer electronics products, medical equipment, and aerospace solutions, as space-limiting conditions and dynamic environment posed significant design subtleties.

1. The Art of Bending and Conforming

The most prevalent advantage of flexible PCBs is their flexibility, which allows them to bend and conform to almost any design or surface. Unlike rigid PCBs, which are unable to assume an arbitrary form because of their defined nature, flexible PCBs can be forced into extremely tight configurations or curved objects. This specific scenario makes them appropriate for use in locations with less area or whenever certain contours are required.

2. Maximizing Space Utilization

At present, compact electronic devices are in great demand among consumers, which makes space optimization a critical criterion for hardware designer. In this regard, flexible PCBs have a high indicator of this characteristic, due to the possibility of efficient use of the available space. Bending and folding make it possible to develop complex layouts in conditions of limited space, which, in turn, opens up additional opportunities for using functional gadgets and reduces their total area. Such opportunities are highly demanded in wearable devices, medical gadgets, and electronic devices.

3. Durability in Motion

Though they are flexible, flexible PCBs are also highly robust and resilient in most environmental conditions. They can be twisted and bent many times while maintaining their electrical properties and mechanical strength . This makes flexible PCBs ideal for applications with substantial motion or vibration, such as robotics, aerospace engineering, and automobiles.

4. Streamlining Connections

Flexible PCBs present a simple methodology of linking multiple components or devices. The capacity to bend, wrap, and twist makes them an effective means of transporting signals within other, essentially various parts of the computer. As a result, no additional space for big connectors or sophisticated wire harnesses is required. The fewest possible proven weak points make failure less probable once again.

5. Lightweight and Portable

Most prominently, flexible PCBs are built to be lightweight. While rigid PCBs are relatively dense and weighty, flexible PCBs tend to be thin and lightweight, ensuring they are ideal for scenarios where the weight of a PCB is a major consideration. For example, in the aerospace industry, the reduction of a single ounce can result in substantial financial and performance benefits.

6. Thermal Management Mastery

Finally, it is important to underline that flexible PCBs have a much higher thermal management capability. Due to their bendable and thinner nature, they are more effective dissipating heat without hotspots, and so ensure excellent performance, even in high-temperature conditions. This is particularly useful for systems such as automotive electronics.

7. Applications Galore: Exploring the Versatility

Wearable Technology

Wearable technologies have been one of the primary impulses behind the increase in flexible PCBs popularity. Different circular gadgets such as clothing, accessories, and devices like medical instruments become more advanced without compromising wearability and practical utilization. Whether used for smart watches or fitness measures, flexible PCBs are the PCB solution utilized.

Automotive Electronics

The automobile industry widely recognizes that, besides their durability, flexible PCBs with space-saving properties also promote powerful electronic control, presenting a whole new array of benefits. These networks are not unusual in many automobile systems, like headlights, vehicle dashboards, and car connectivity. The fact that they can stand vibrations and very high temperatures may be the reason for their selection for high conditions found in vehicles.

Medical Devices

Within the realm of medicine, the value of flexible PCBs is impossible to overestimate. These devices are often used in implantable devices like pacemakers and neurostimulators for their biocompatibility and ability to fit the human body perfectly due to their flexibility. Thin PCBs are also used in diagnostic equipment and patient monitoring systems designed to be as small and ergonomic as feasible.

Aerospace and Defense

Aerospace and defense sectors are hunting for lightweight, yet very-reliable electronics solutions. Flexible PCB partially accounts for these stringent conditions with its resistance to vibrations, semi-fragility, and low weight. From avionics systems to deploy part of state and even military areas, they are offered as markers of credibility and performance in critical applications, avionics systems, state components, and military equipment where such quality features are needed.

Consumer Electronics

The electronic technology market has few problems with adaptability of the flexible PCBs due to the fact of space saving options and appealing designs. The reason for the popularity of the flexible PCBs is the fact that people can make their appliances and products portable, sleek and stylish. From manufacturing of smartphones to tablets and gaming consoles, the segment of flexible PCBs provides the ease of creation of such appliances without adding to their weight or making them clunky.

Industrial Automation

Flexible PCBs have widespread usage in industrial automation contexts such as robotics, automation systems and sensors. For this reason, screws with a thread form that allows axial stresses to be evenly distributed, and hydraulic oil-lubrication are advantageous in such harsh environments because they allow the devices to operate reliably and provide prolonged service life.

Renewable Energy

As the renewable energy sector has adopted the benefits of flexible PCBs in different uses, including solar panels and wind turbines, the sector has been able to increase its technical efficiency. Their lightweight and robust designs offer seamless integration into renewable energy schemes, forming a key technology component for sustainable and environmentally friendly solutions.

Internet of Things (IoT)

The boom of the Internet of Things (IoT) leads to a high volume of flexible PCBs’ requirements. The deployment of these circuits is compatible with virtually all IoT elements thereby marking easy interaction and data exchange in smart homes, industrial automation, and other connected fields.

Lighting Solutions

Flexible printed circuit boards (PCBs) have certainly changed the dynamic by allowing LED lighting to be more flexible, cost-effective, and energy efficient. Besides flexible LED strips and the curved lighting, these circuits made it easy, not only to create a wide range of( different from the others or peculiar) design options, but also enhance the user experience itself.

Prototyping and Rapid Development

The emergence of prototyping and rapid development in this world leads to the PCBs being flexible becoming more advantageous. They are flexible and easy to change, giving a chance for a fast determination and control over the design and testing features, and speeding up the product creation process.

Conclusion

With the passage of time, semiconductor design proved that the flexible PCBs were the right choice for the future. This multi-functionality of flexible materials combines different characteristics – durability, space-saving features and sustainability. It has allowed human beings to create new markets in various industries. As we grow from wearables tech to aerospace and defense, ultra-thin flexiform PCBs become the way to go for compact, dependable, and highly efficient electrical solutions.

+ There are no comments

Add yours